Subminiature-C Feedthrough on CF Flanges

Subminiature-C (Sub-C) multipin hermetic feedthroughs are designed for applications where space is limited inside your vacuum chamber.

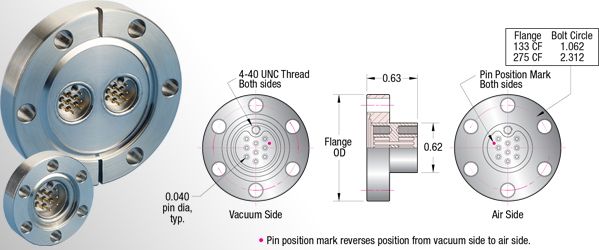

This compact and unique 9-pin design allows installation into a 1.33-inch CF flange or two feedthroughs on a 2.75-inch conflat CF flange. Nine gold-plated pins are arranged in a straight through pin-to-pin design and are hermetically sealed and electrically insulated in a stainless steel shell using the latest in glass-ceramic bonding technology.

| Electrical | |

|---|---|

| 500 VDC 5 Amps* |

| * For proper heat dissipation, a maximum of 20% of the pins on a feedthrough may carry the maximum pin current at any given time. | |

| Material | |

|---|---|

|

|

| * Peek is a Polyether-ether-ketone thermoplastic. | |

| Vacuum Range | |

|---|---|

| 1x10-10 Torr |

| Temperature Range | |

|---|---|

|

|

| * Overall assembly ratings must be adjusted to that of the lowest rated component. |

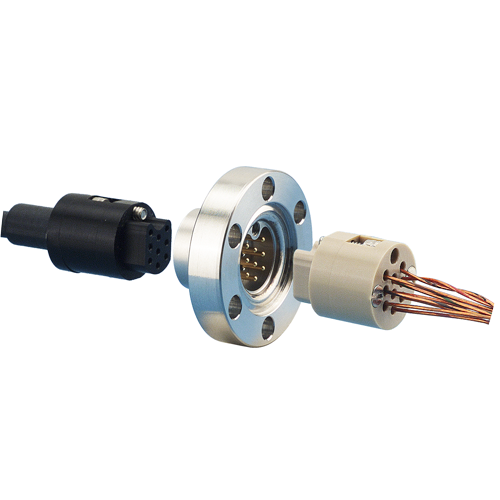

Sub-C CF Feedthrough Flange "Kit" Features:

- All of the above features (Feedthrough Flange)

- In Vacuum cable assembly:

- PEEK Sub-C connector to Kapton insulated cable assembly, 19-inches long.

- Air Side cable assembly:

- Delrine Sub C connector to cable assembly, 96-inches long.

All feedthroughs are mounted on CF Flanges that incorporate the industry standard "captured copper gasket" sealing principle, making it easy to mount to your existing CF Flange ports.

Subminiature-C Ultrahigh Vacuum (UHV)

Accu-Glass Products Subminiature-C multi-pin hermetic feedthroughs (also known as Sub-C or Type-C) are designed for applications where space is limited, or where Subminiature-D (Sub D) connections will not fit. Its compact design allows installation into a 1.33 inch CF metal seal vacuum flanges, or two (2) Subminiature-C 9-Pin feedthroughs on a 2.75 inch CF flange.

Nine gold-plated pins are arranged in a straight through pin-to-pin design and are hermetically sealed and electrically insulated in a stainless steel shell using the latest in glass-ceramic bonding technology.

Air and vacuum side connectors are fitted with a captured stainless steel socket-head screw providing a means of securely locking connectors to a mating feedthrough. On the vacuum side, Kapton® insulated cable assemblies fitted with PEEK connectors are available to meet the rigorous demands of (UHV) ultrahigh vacuum environments. In-vacuum connector screws are vented and the feedthrough's threaded-boss doubles as a connection polarizing key. Pin assignment is identified with a permanent surface mark, which clearly locates the Pin-1 position. UHV Subminiature-C feedthroughs and cables are sold individually or as kits, where each kit contains a feedthrough and both vacuum and air side cable assemblies.

Warning: Please review 'Glow Discharge Graph' and how voltage rating is affected by pressure change.

Features

- Subminiature-C 9-Pin Interface

- High temperature rated to 250°C

- UHV compatible construction

- Conflat® compatible mounts

- Kapton® Insulated Vacuum Cables

- PEEK or Macor® Connectors with Locking Screws

- Air Service Cables / Connectors

- Custom Solutions on Request

Specifications

| Electrical 1, 2 | |

| Voltage | 500VDC |

| Current | 5A |

| Material | |

| Shell | 304 Stainless Steel |

| Pins | Au Plated, Ni-Fe |

| Seal / Insulator | Glass-Ceramic |

| Connector, Air | Delrin® |

| Connector, Vacuum3 | PEEK |

| Connector, High Temperature | Macor® Ceramic |

| Vacuum Range 4 | |

| UHV, Ultrahigh Vacuum | 1x10-10 Torr |

| Temperature Range 5 | |

| Feedthrough | -200° to 250°C |

| CF Flange | -200° to 450°C |

| Connector, Delrin® | 80°C |

| Connector, PEEK | 250°C |

| Connector, Macor® Ceramic | 400°C |

| Thermal Gradient | 25°C / Minute |

| Notes |

- Electrical ratings are maximum test values, with feedthrough's vacuum side at ≤ 1x10-4 Torr. Feedthroughs are intended for instrumentation applications carrying low level signal voltage and current.

- For proper heat dissipation, a maximum of 20% of the pins on a feedthrough may carry the maximum pin current at any given time.

- PEEK is a polyether ether ketone thermoplastic.

- Leak tested to 5x10-10 Standard cc/sec of He.

- Overall assembly ratings must be adjusted to that of its lowest rated component. For cryogenic service, the lowest recommended temperature is -200°C

- Unless designated a 'kit,' connectors and cable assemblies are not included with feedthrough and must be purchased separately.